|

| |

|

When a sailing

rig is in use, considerable forces can be generated

throughout the rig by the energy in the wind, and

the forces can change rapidly in degree and

direction. Therefore, if we are contemplating a

jointed mast such as the Transition Rig, we have to

be sure that the joints can withstand the forces

being applied. Also, because the rig will be

extending and folding, as well as rotating about its

vertical axis when in use, we will not be able to

attach stays or shrouds to support the mast - it has

to be free-standing. (The windsurfing version is a

little different in this regard, since the sailor

provides support to the rig by holding on to the

boom.) At the same time, the mast cannot be unduly

heavy, since additional weight higher up would upset

the stability of the craft. Therefore, there are a

number of design issues to keep in mind while

developing the Transition Rig mast. Here I shall

review my experience with different types of joints.

---

|

|

A)

Biology-inspired joints

|

|

|

|

|

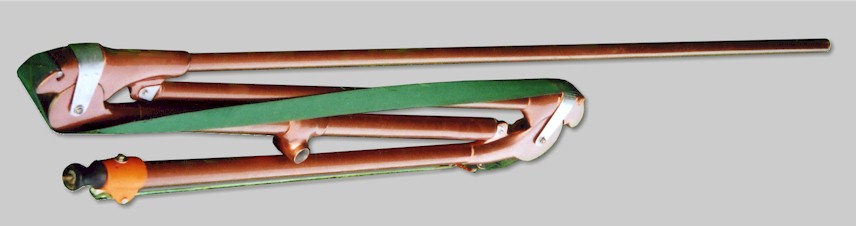

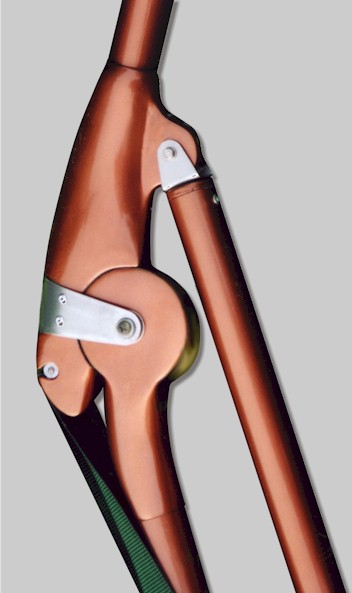

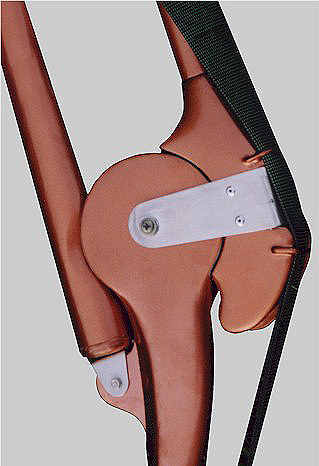

When I began making jointed

masts, I modelled the joints on biological joints. I used deep

concavo-convex articular surfaces for the hinge joints because I

knew from my experience as an anatomist that these were very stable

and could resist twisting forces well. Straps made of aluminium or

thin stainless steel were used to hold the joints together, rather

like the collateral ligaments of a biological joint. To ensure that

the joints were not too heavy, I made them from hollow composite

materials such as glass or carbon reinforced epoxy resin.

Making the joints was very time

consuming. First the exact shapes of the components had to be

modelled in wood, and then moulds were made in which the composite

components could be formed. (Notes on mould-making

here.) It took me several months to create a new mast

using these methods. If I changed any variables in the mast design

as a result of testing I then had to redesign the joints and make

new moulds.

As time went by, I came to the

conclusion that I needed a more rapid way of making masts and joints

so that I could try out ideas quickly and speed up development of

the Transition Rig. I had found that very small changes in the

geometry of the mast, for example the positioning of the joint

pivots, could radically affect the way it worked. I made the

conscious decision to simplify the design as much as possible, and

began making the joints in a different way. This is summarised in

the next section. |

|

|

|

B)

Simplified joints

|

|

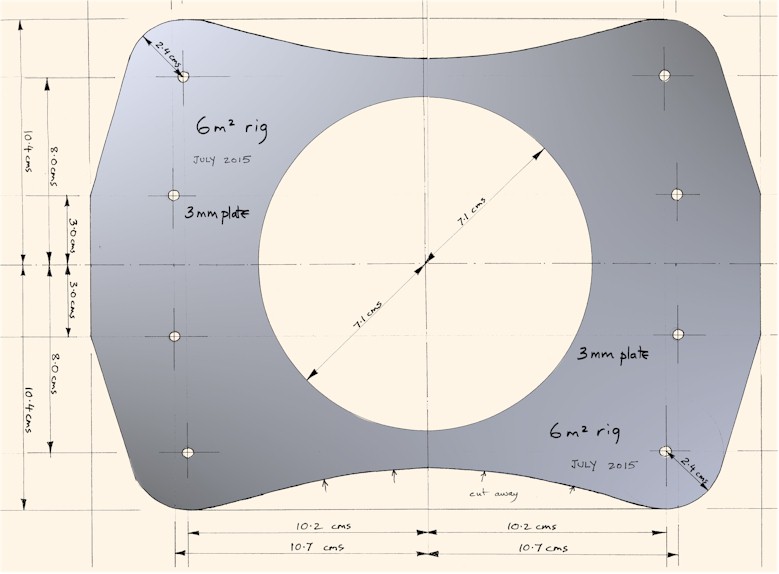

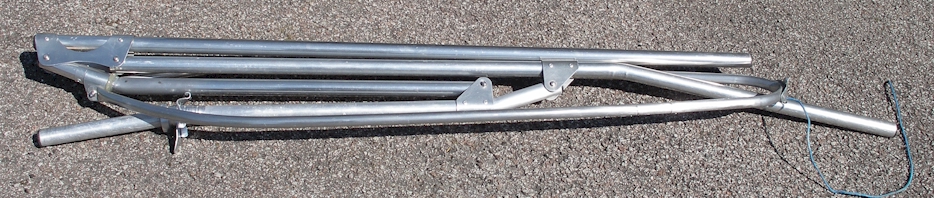

I began to make

joints from thin aluminium plate wrapped around the mast tubes and

pop-riveted in place. In this way, I could quickly change the

geometry of the mast by drilling the pivot holes in different

places, and a new mast could be made in hours rather than months.

The pivots were made from M6 stainless bolts and Nyloc nuts.

To simplify the bending of the

joint plates I made formers to suit the different tube diameters I

was using. First, the plate is cut to size and drilled - the image

below shows an upper joint plate for the 6 sq m rig:

|

| The flat plate is clamped in

position on top of the former and then hand pressure applied to each

side of the plate to begin the bend. When the sides have dropped

below about 45 degrees from the horizontal the whole unit can be

placed upside-down in a vice to continue the bending in a controlled

way until the cheeks of the joint plate are parallel. The plate can

then be attached to the mast tube with pop-rivets. |

.jpg) |

|

|

The simplified

aluminium joints work well and are very practical. I

have to admit, though, that I like the look of the

biology-inspired joints, and one day, when the

design of the mast has been optimised, I would like

to make myself a mast using them for purely

aesthetic reasons.

|

|

|