|

|

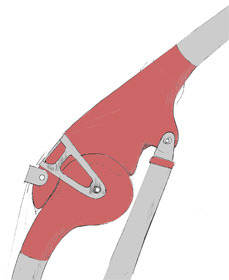

I was introduced to this technique of mould-making by Hans

Arkeveld, the renowned Australian artist. Thank you, Hans!

I use this method when making

biology-inspired joints for prototype Transition Rigs.

|

|

|

The first step is to make

full-sized patterns of the shapes that are to be moulded.

Usually I make the shapes from wood, coat them with epoxy resin,

and then paint them.

|

|

|

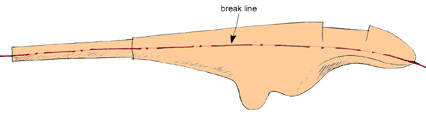

| The next step is

to decide the plane along which the mould will separate into two

halves. The position of this 'break line' will depend on the shape

of the pattern. (More complicated shapes may require a mould to

separate into more than two parts.) |

|

|

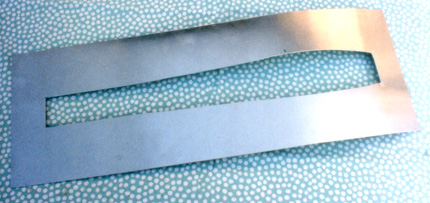

| There are

different ways to create a surface along this line, but for the

relatively simple shapes that I am using I cut out a piece of thin

aluminium sheet and then curve it to fit the break line. |

|

|

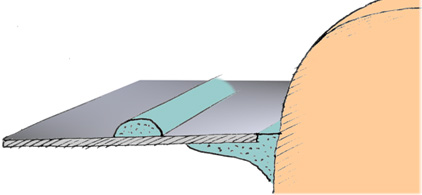

| With the pattern

supported in a suitable position, the aluminium sheet can be held in

position with modelling clay (Plasticine™)

which is also used to fill any small gaps between the cut-out in the

plate and the pattern. |

|

|

| A narrow strip of

modelling clay is placed on the metal surface about 2 cms from the

pattern - this will produce a ridge and corresponding groove in the

two halves of the mould, and help to key them together.

In the next step, silicone rubber

will be used. Silicone rubber does not set properly when it comes

into direct contact with modelling clay, so the exposed clay must be

painted with shellac. (Shellac is a fast-drying material made from

the wing cases of a beetle dissolved in methylated spirit.)

After two coats of shellac have

been applied and allowed to dry, a thin film of petroleum jelly

(Vaseline™) is smeared over the

shellac-painted and exposed aluminium surfaces. |

|

|

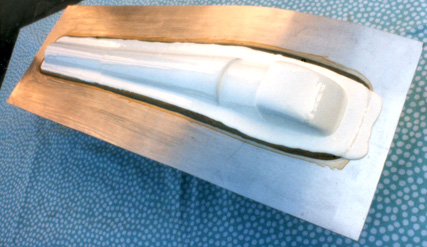

| Silicone rubber is

then poured over the pattern. I use Silastic E RTV™

by Dow Corning. The rubber is mixed with a catalyst in the ratio of

10 parts rubber to 1 part catalyst. This is a viscous material and

has to be coaxed to flow evenly over all the surfaces and fill all

the nooks and crannies. It takes approximately 24 hours to set at

room temperature.

After the rubber has set, it will usually be necessary to apply a

second and perhaps a third layer of rubber, depending on the size of

the mould being made. If the pattern has any sharp angles or other

potentially weak areas, the rubber can be reinforced with pieces of

glass fibre cloth placed in those areas and saturated with the

rubber. |

|

|

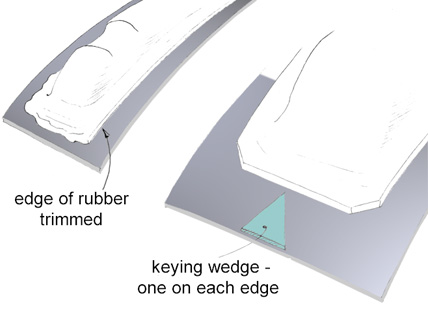

| When the rubber

has cured completely (about 2 days after the final coat) the edges

can be trimmed with a sharp knife so that the inner rubber mould

will fit snugly in the 'mother mould' that is going to be made next.

Also, triangular keying shapes made from modelling clay can be added

at this stage and painted with shellac.

The rigid mother mould will be

built up around the outside of the rubber mould to give it support. |

|

|

| Mother moulds can

be made from various materials. Perhaps the most convenient is

quick-setting Plaster of Paris, although the finished mould is heavy

and is breakable. I prefer to use glass fibre/epoxy resin composite

which gives rise to a light and strong mother mould.

A layer of petroleum jelly is

first applied to all the surfaces that will be in contact with the

mother mould. This will facilitate separation at a later stage. The

edges of the mother mould are built up first with narrow strips of

glass fibre cloth and resin butted up to the edge of the rubber

mould. Six to eight layers will be needed. Then glass fibre cloth

can be laid over the entire surface (rubber and edges) and saturated

with resin. Four to six layers of cloth will be enough.

To further strengthen the edges

of the mother mould, add strips of plywood, using car body filler

paste as the adhesive to take up any surface irregularities. Then a

few more strips of glass fibre cloth can be added around the edges

to add further strength. |

|

|

| To complete this

half of the mould, a wooden base is added to support the mould when

it is turned over.

This is a good time to trim the edges of the

half-mould with a saw to remove surplus glass fibre composite and

wood. |

|

|

| The whole

work-piece can now be turned over and the temporary supports for the

pattern removed. The aluminium sheet for the break line can be

lifted off, and all traces of modelling clay removed.

The sequence is now repeated for

the second half of the mould. Petroleum jelly is smeared thinly over

the exposed surface of the first mother mould. The layers of rubber

are built up, reinforced where necessary, the edges trimmed, and

then the second half of the mother mould built over the form.

|

|

|

| Finally, a base is

added for this half of the mould, the edges are trimmed, and holes

are drilled for bolts that will clamp the two halves of the mould

together. |

|

|

| The finished mould

can be used to make multiple copies of the original shape. In this

example, a thin coat of epoxy resin was applied to the inner surface

of both mould halves, allowed to polymerise, and then unidirectional

carbon fibre was laminated into the mould halves to build up a

sufficient wall thickness. A length of aluminium tube and a shaped

piece of wood were fitted internally for reinforcement, and then

before the resin polymerised the two halves of the mould were

brought together and bolted. The mould was then rotated to ensure

even distribution of the resin and effective fusion of the internal

components and the two composite halves.

After polymerisation, the joint

component can be removed from the mould and prepared for use. If

required, an expanding polyurethane foam can be injected into the

hollow core to fill it and add strength. |

|

|

|

|

This joint

component has been sectioned longitudinally to show the

internal structure: the aluminium tube, shaped wooden

reinforcement, and foam filling.

|

|